© Copyright Red Lodge Helicopters 2024

These pages will show the build of the first of our Seaking’s, for information on the kit click here

We’ll be posting updates for the Sea King as and when things progress, so keep checking back for latest news.

‘....>

.

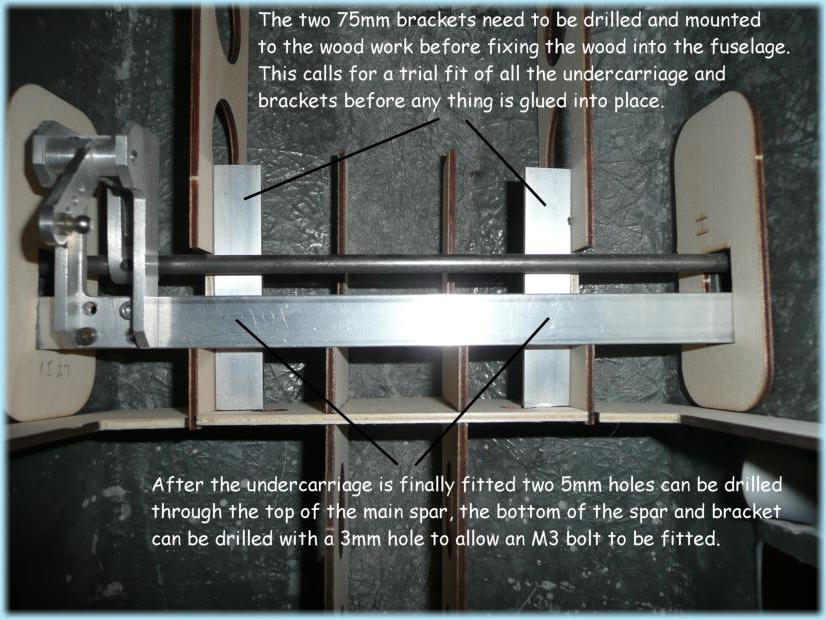

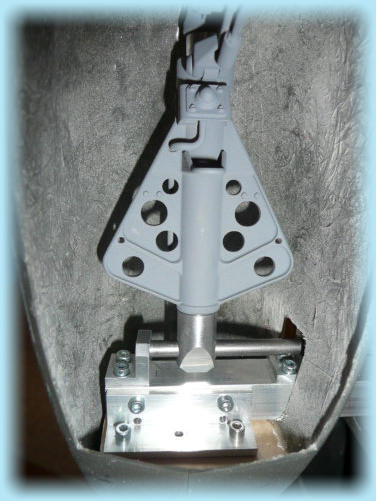

The section below is a guide to assembling the undercarriage.

Cut two holes in the fuselage side to allow the

main spar to pass through.

The position for this is marked in the moulding.

The position for the spar to enter the

wheel pods can be marked using the

front moulding line as a reference

point.

This is the same for both wheel pods.

The bracket needs to be attached to the

woodwork with 2 M3 x 10mm bolts and

captive nuts, using the previously cut

hole to align the bracket.

The woodwork can then be glued into place

taking care to align it inside the wheel pod

to give the correct angle of the pod in

relationship with the fuselage.

Also making sure that the pod is at 90 degrees

to the main spar.

Although the undercarriage mechanism is supplied pre assembled it will

need to be taken apart to enable it to be fitted into the fuselage.

When re-assembling great care must be taken NOT to over tighten the

M3 x 8mm bolts which go into the main spar. These need to be thread locked

when final fitting.

IMPORTANT

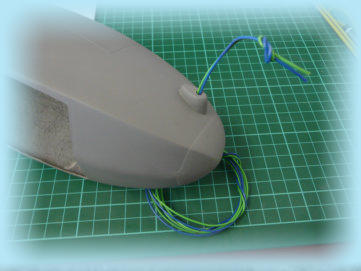

If your going to fit nav lights its a good

idea to run the wiring for the LED’s at

this point, before you glue in the

woodwork.

This is the paint scheme for the first model.

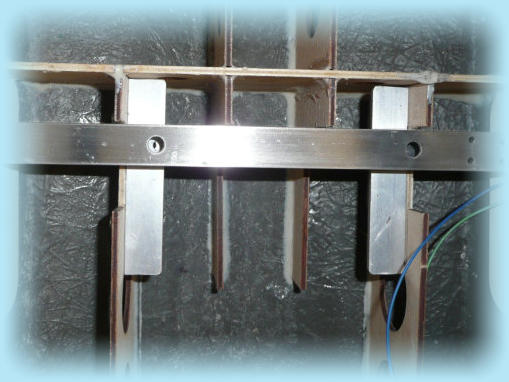

The brackets that hold the 6mm rod are fixed inside

the wheel sponsons.

The winglets can then be trimmed to fit

and glued in place.

As on the full sized helicopter the

winglets don’t fit flush up to the

side of the fuselage